BREYER CellProtect

Extrusion line for EVA and POE solar film

BREYER CellProtect: high-tech on the sunny side of life

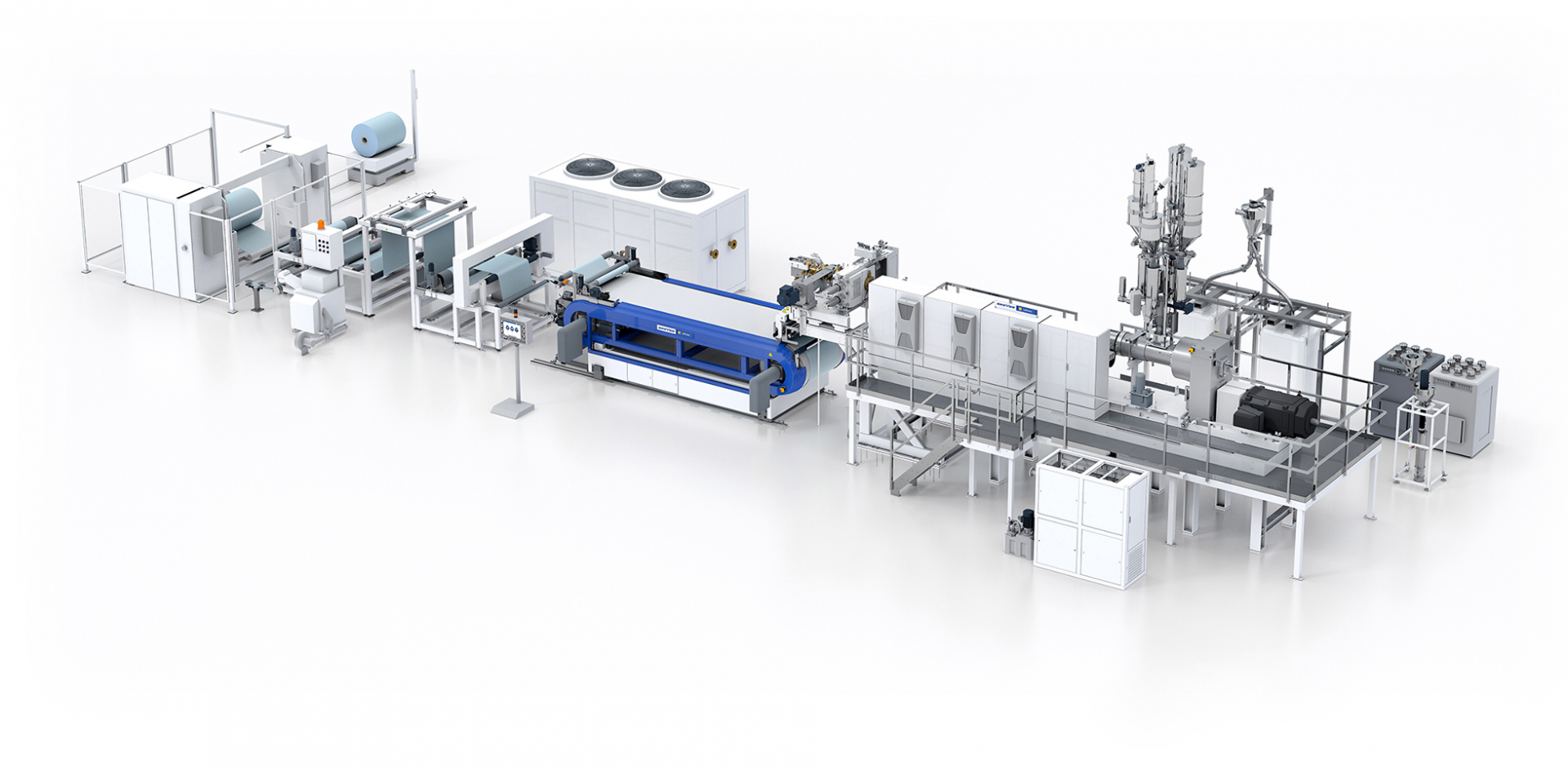

The convincing extrusion technology for the production of low shrinkage solar encapsulant film for PV-modules. BREYER offers the complete line including proofed recipe and service.

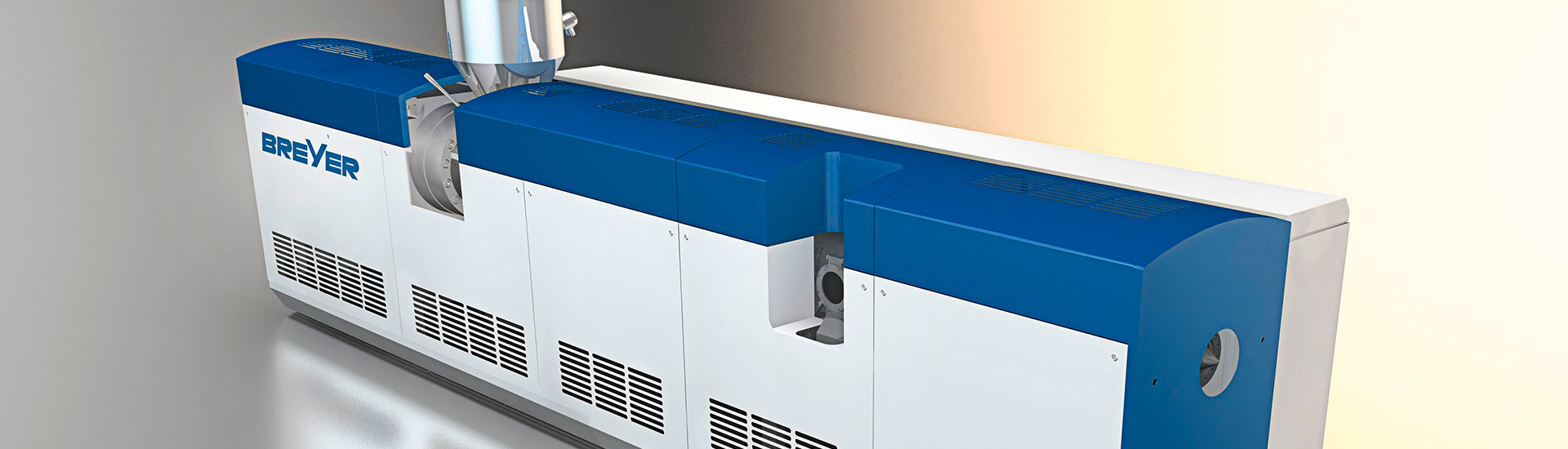

Dosing system, extruder, die, process unit for forming – cooling – embossing, winding

The BREYER CellProtect system allows much higher speed and therefore higher output compared with conventional systems. Since standard extrusion systems only provide a limited line speed/output, BREYER has developed a forward-looking system for a profitable production of low - shrinkage solar encapsulant film.

Get more of BREYER energy solutions here.

Avantages

- Huge output

- Fast start-up

- lowest shrinkage rate

- No interlayer film

- No carrying paper/film

- No post-annealing

- Different embossing pattern

- For solar as well as other applications

- Production of sample films for premarketing and approval procedure

- Trials and material tests are possible on BREYER‘s pilot line

Technical data

| Film thickness | 0,3 – 0,8 mm |

| Film width | up to 1300 mm |

| Performance | 350, 600 kg/h |

| Material | EVA, POE |

| Versions | single layer, multilayer, embossed, smooth |

Examples of application

BREYER CellProtect - high-tech on the sunny side of life

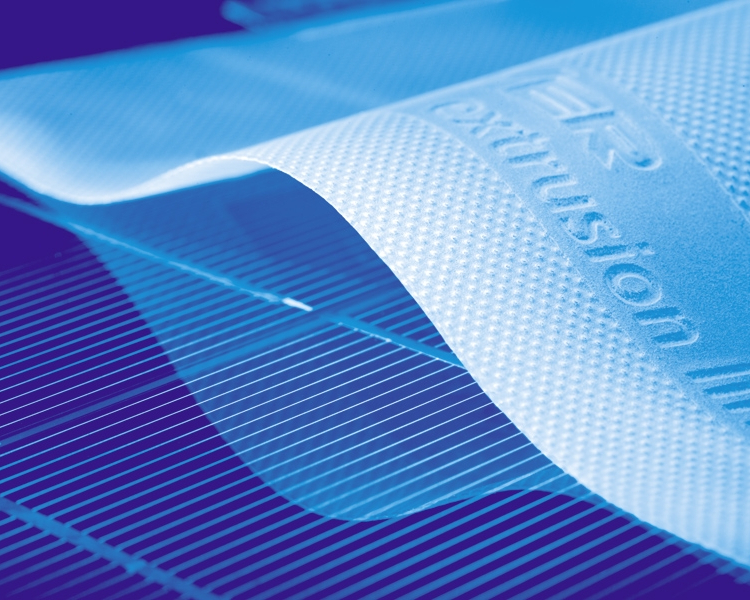

EVA film with individual embossing structur

EVA film with special structure - no interlayer necessary

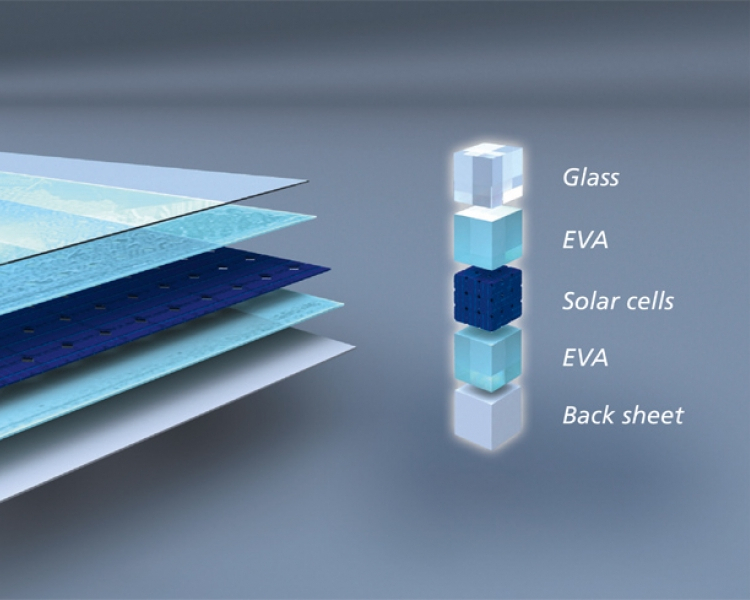

Typical configuration of a PV modul